KDPOF (leading supplier for high-speed connectivity over fiber optics in harsh environments) proudly announced their strategic partnership with Hinge Technology (China-based leader in advanced vehicle electronics architecture) to solve key technical issues in the industrial application of optical communications in vehicles.

Strategic Partnership to Advance Automotive Optical Communications for Future Network Demands

For the development and mass production of in-vehicle electrical and electronic architecture of optical fiber communications, Hinge Technology utilizes ICs from KDPOF to design integrated optical modules combined with automotive-grade connectors and optical fiber harnesses to design the electrical electronic architecture (EEA).

Yang Jun is CTO of Hinge Technology

“The widespread application of optical communications in automotive production faces challenges, including harsh environmental conditions and tough requirements for low cost and high reliability,” stated Yang Jun, CTO of Hinge Technology. “Our collaboration with the leading upstream supplier, KDPOF, accelerates the industrialization of vehicle communications system products based on 1 to 50 Gbps optical communications.”

Carlos Pardo is CEO and Co-founder of KDPOF

Carlos Pardo, CEO and Co-founder of KDPOF added: “We’re proud that Hinge Technology has chosen our transceiver ICs for optical gigabit connectivity in harsh environments. At the recent Automotive Ethernet Summit in Shanghai, China, we showed our first joint project: a plastic optical fiber camera by Hinge Technology based on our well-proven KD1053 IC and integrated KD9351 FOT (fiber optic transceiver).”

Surround View System with High-speed Fiber Optics Camera

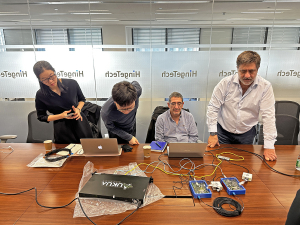

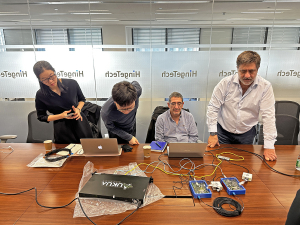

Joint demo of high-speed camera at Automotive Ethernet Summit in Shanghai, China

Using KDPOF components, Hinge Technology has developed an optical fiber camera. It can be paired with an optical fiber surround view host, resulting in a high-speed optical communications 360-degree surround view system or a reverse image system. The camera utilizes a 2MP high-quality image sensor for data collection, which is processed and transmitted via plastic optical fiber to the controller for image display or processing. Optical fiber cameras can achieve a stable transmission distance of up to 40 meters and deliver high-definition, real-time images. By comparison, LVDS coaxial cameras have no relay transmission capability and are limited to 15 meters.

The KDPOF EVB9351AUT evaluation board provides an extensive platform for testing the KDPOF KD9351 and KD1053 transceivers, designed for the 1000BASE-RHC PHY implementation in automotive optical networks. The KD9351 IC, with dimensions of 7 mm x 8 mm in an LGA-36 package, handles the PMD sublayer of the physical layer. The KD1053, sized at 7 mm x 7 mm in a QFN-56 package, manages both the PCS and PMA sublayers as specified by IEEE Std 802.3bvTM-2017. This setup supports data transfer rates of 1,000 and 100 Mbps.

Additionally, the board features an SFP slot, enabling it to serve as a media converter between the optical 1000BASE-RHC port and various SFP modules. These can include 1000/100BASE-T, 100BASE-FX, 1000BASE-S/LX, direct-attach passive twinax cable, and passive serial loopback configurations.

Joint Research and Design for Future Optical Connectivity

KDPOF team visiting Hinge Technology facilities to work on collaborative projects

In addition to developing optical EEA for vehicle communications, KDPOF and Hinge Technology will extend their partnership to the application of optical communications technology in battery management systems (BMS) for electric vehicles. The companies are collaborating on the development and manufacturing of optical modules and system-on-chips (SoC). They plan to introduce optical-electronic integrated chip packaging technology in regions of China with well-developed automotive industry clusters, establishing FAB facilities capable of packaging chips with bandwidths ranging from 1 to 10 gigabits.

Utilizing Chiplet technology solutions, they are jointly researching and developing advanced chip-on-panel (COP) packaging technology for low-cost, high-reliability optical processors, optical modules, and complementary optical components tailored for automotive optical communications. This initiative aims to ensure production capacity for various automotive optical communications products. Together they plan to develop and manufacture higher-bandwidth optical communications semiconductors in the future, driving continuous upgrades of EEA architecture for the global automotive industry.

Furthermore, Hinge Technology conducts relevant functional verification on mass-produced vehicle models, including assessing packet loss rates, signal transmission losses, optical module heat dissipation, optical module and optical connector optical path coupling solutions, and optical connection reliability in various road environments. Based on the results of real vehicle verification, Hinge Technology develops corresponding solutions and provides feedback on technical issues related to optical chips to KDPOF for resolution.

More information is available in the white paper from Hinge Technology.

About Hinge Technology

Hinge Electronic Technology Co., Ltd., was established in 2014 in Shanghai, China with a vision to driving continuous upgrades of EEA architecture for the global automotive industry. Since its creation, Hinge has pioneered the development of advanced automotive systems and products such as the self-adapting AUTOSAR system, in-vehicle TSN (time-sensitive networking) Ethernet, and optical Ethernet, essential technologies in crafting the electronic backbone for the smart vehicles of tomorrow. Powered by its R&D capability, Hinge has forged strategic partnerships with prominent entities (both upstream and downstream) across the automotive sector around the globe. Hinge has built a manufacturing and testing hub in Zhuji city, a facility encompassing 40 hectares with mass production capacity and delivery capability for OEMs.

English press release PDF

Chinese press release PDF

German press release PDF

TAAS LABS

TAAS LABS

TRUMPF

TRUMPF